Intelligent Logistics, Revolutionizing Efficiency

Precise Navigation, Agile Operation, Building the Next Generation Smart Factory

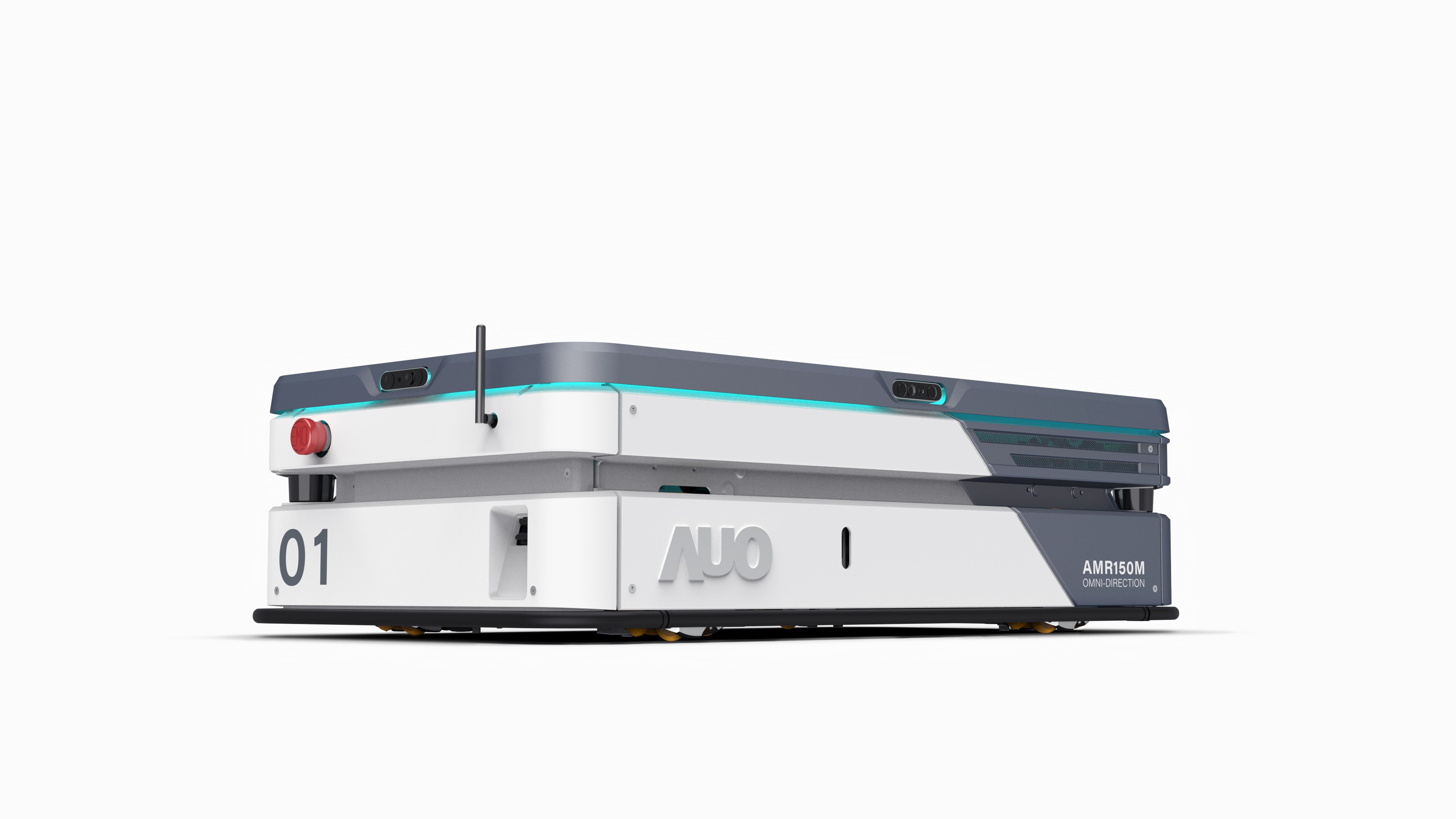

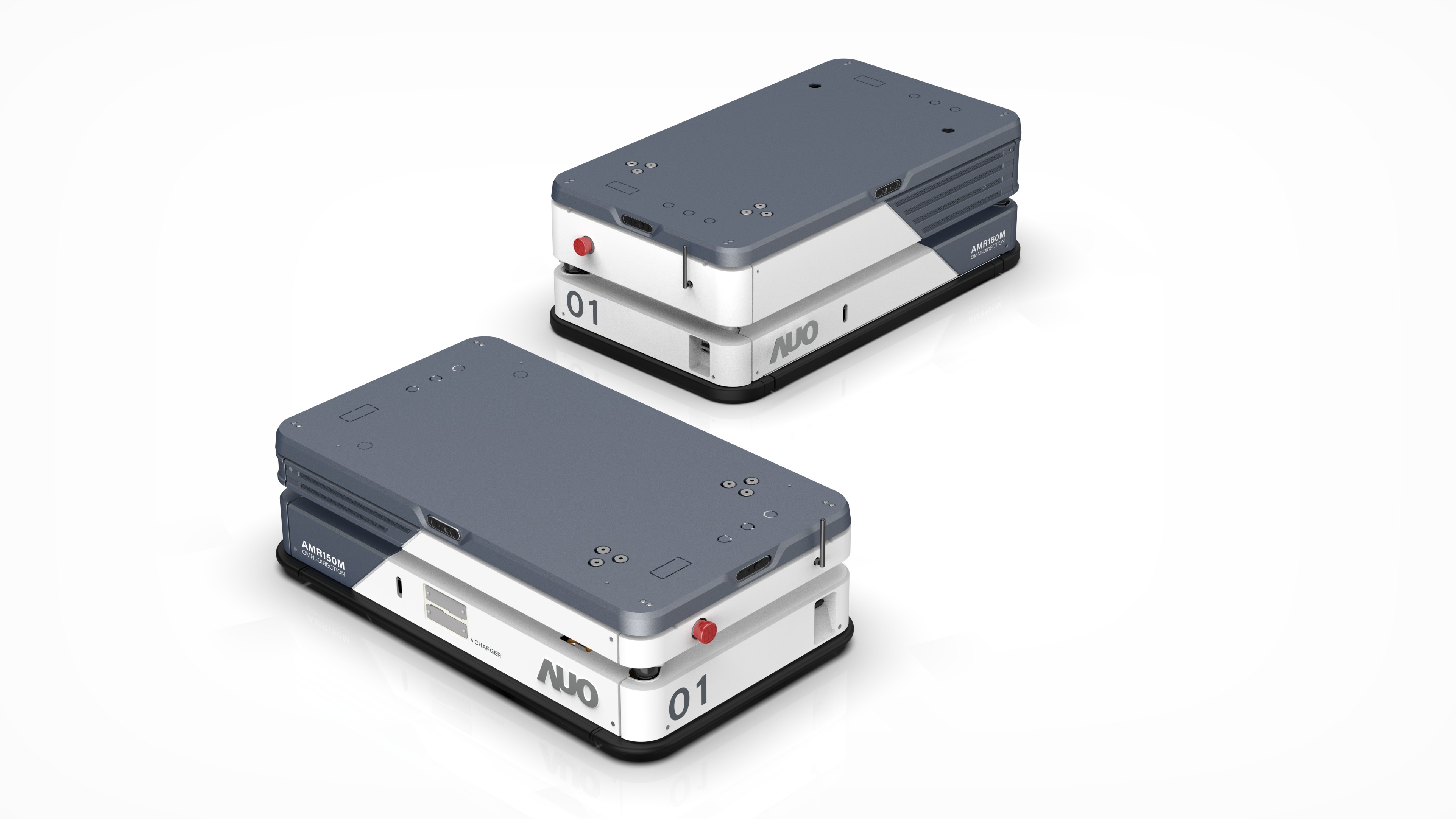

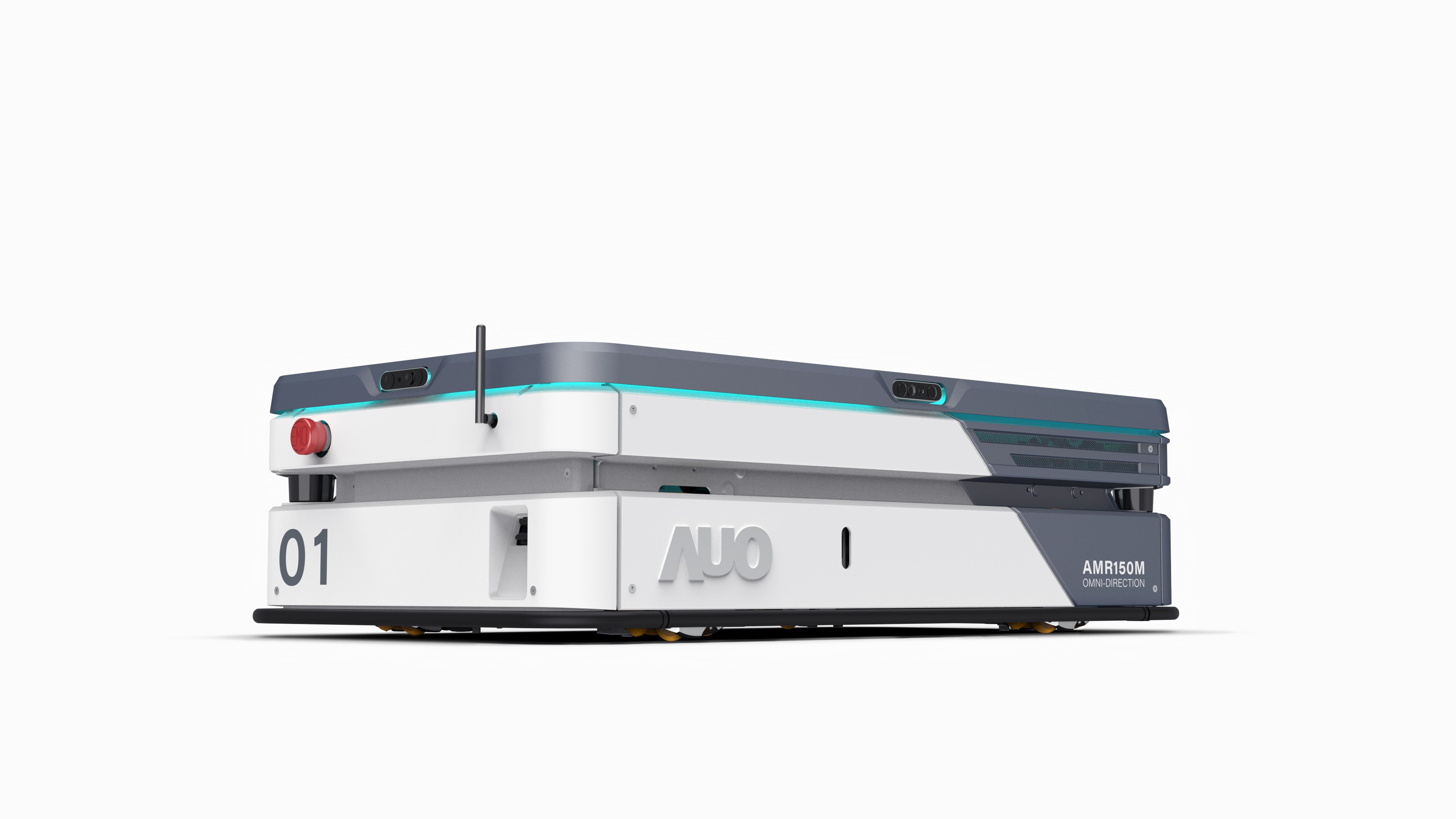

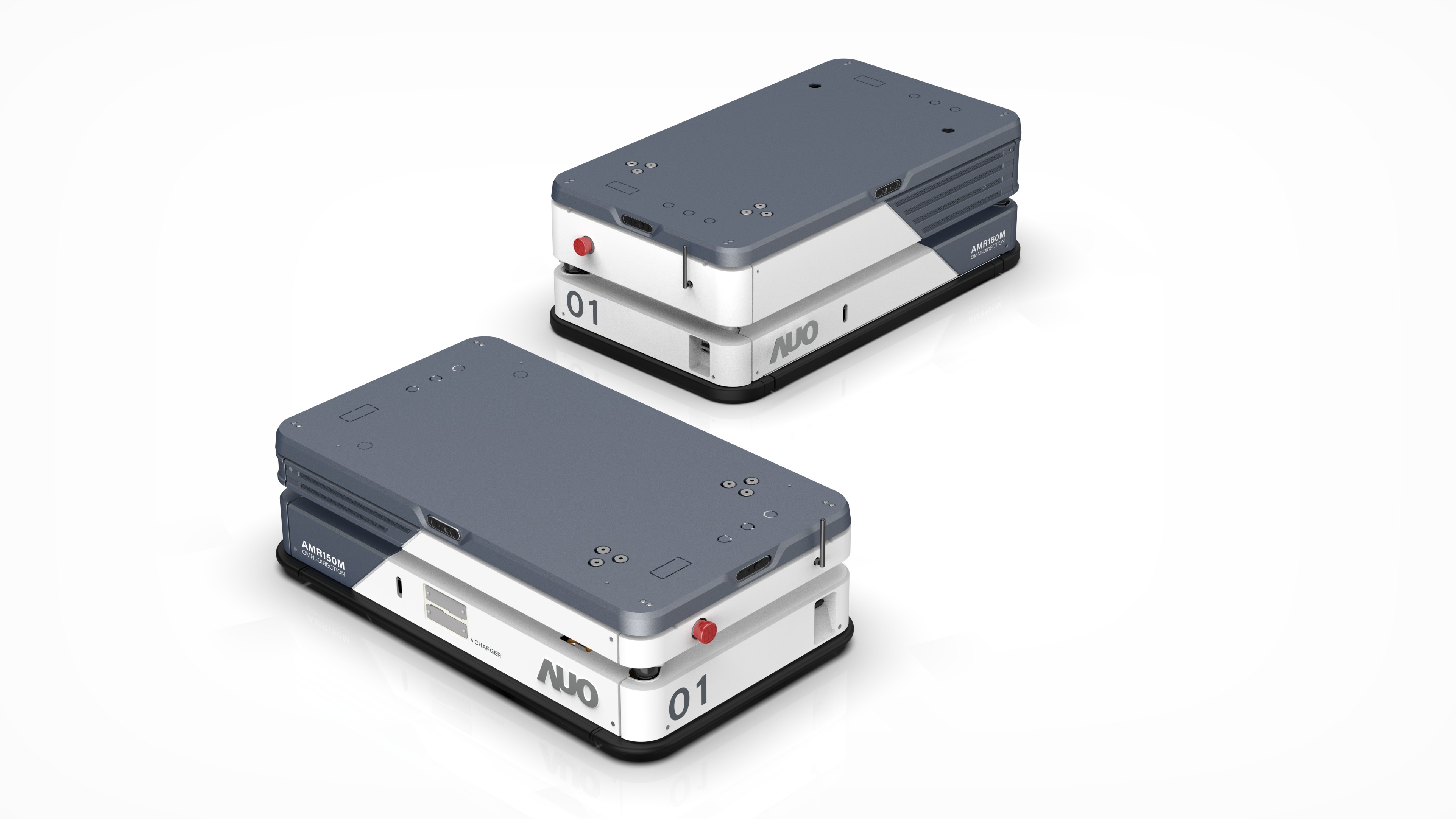

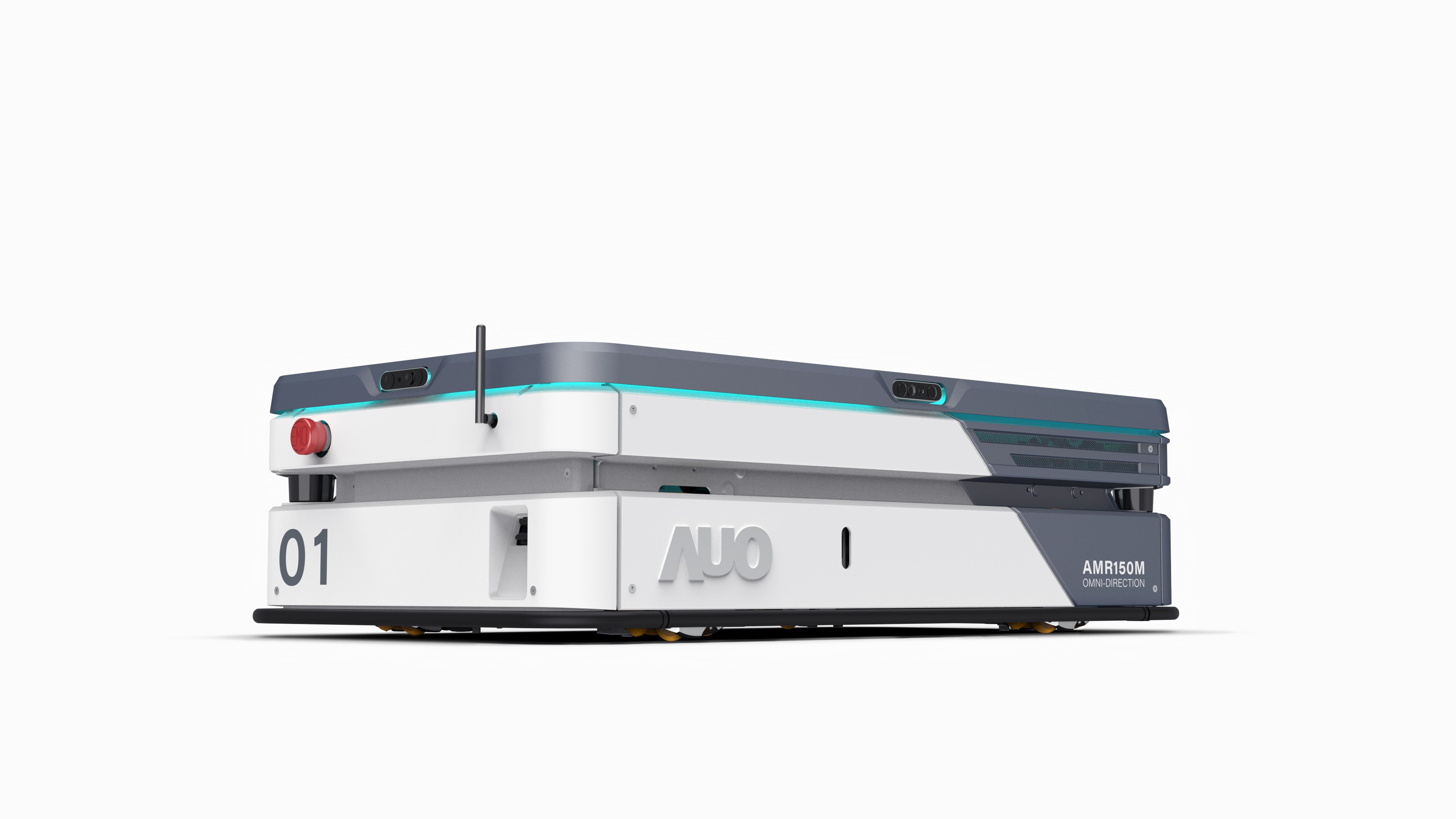

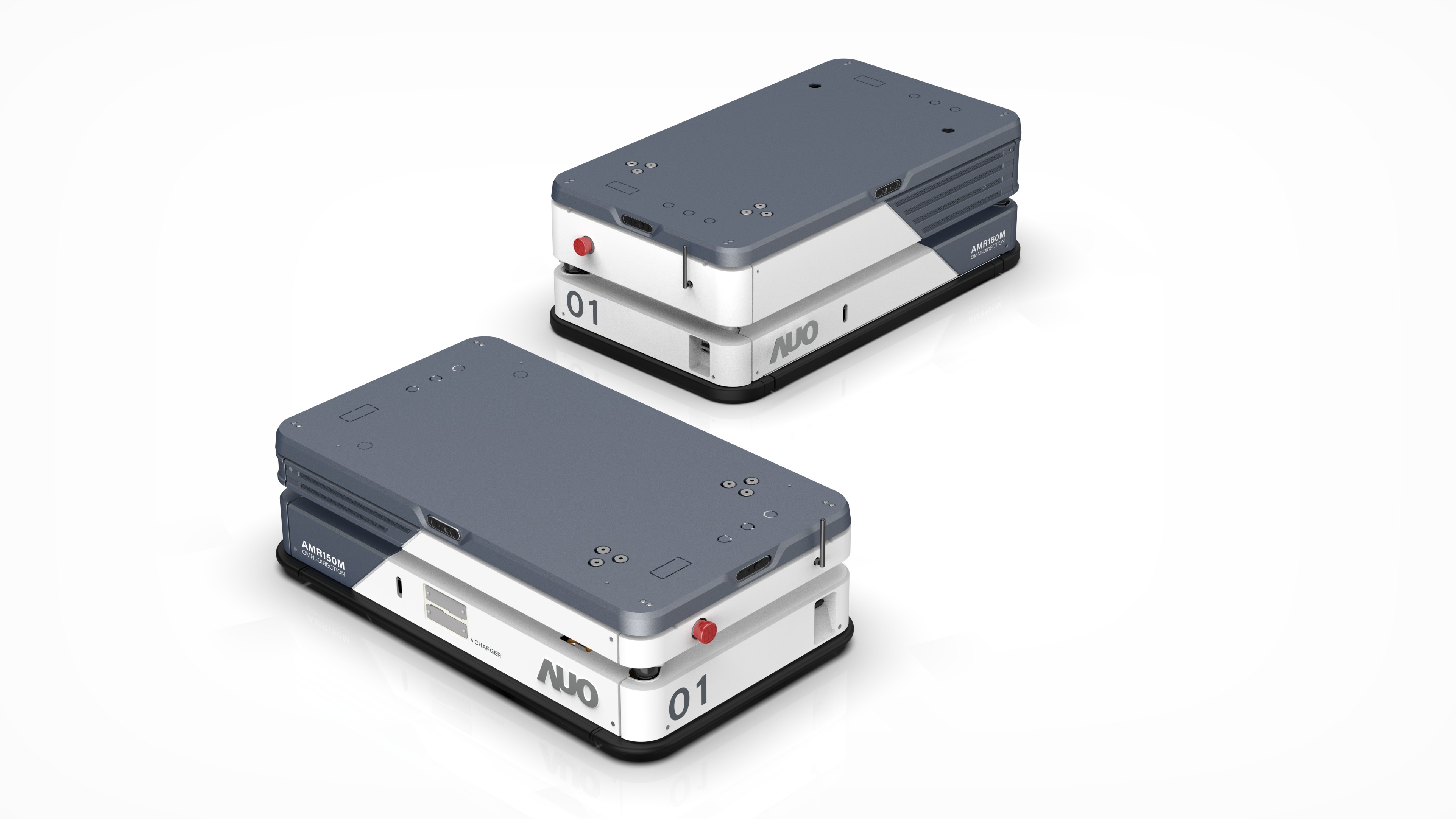

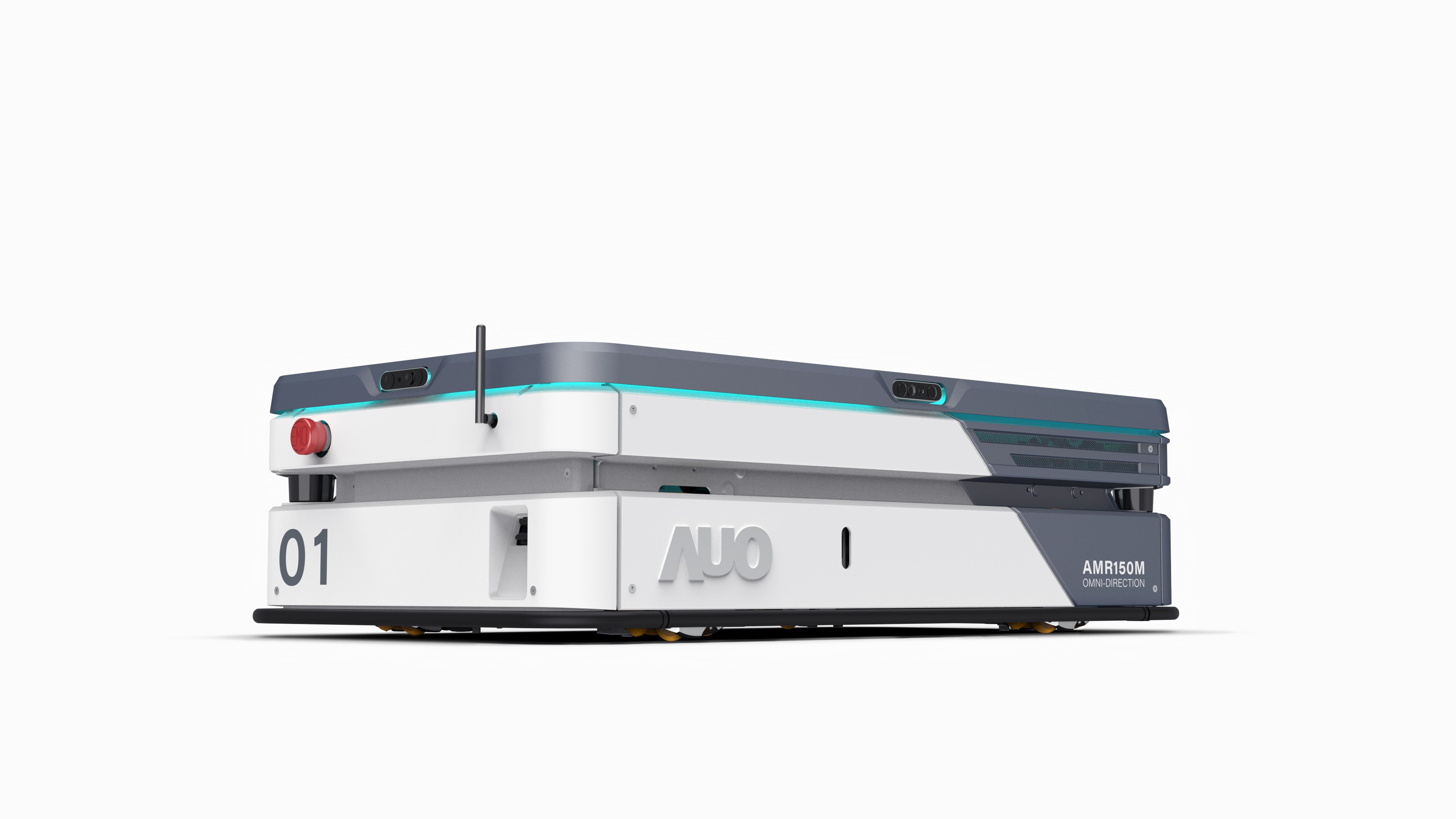

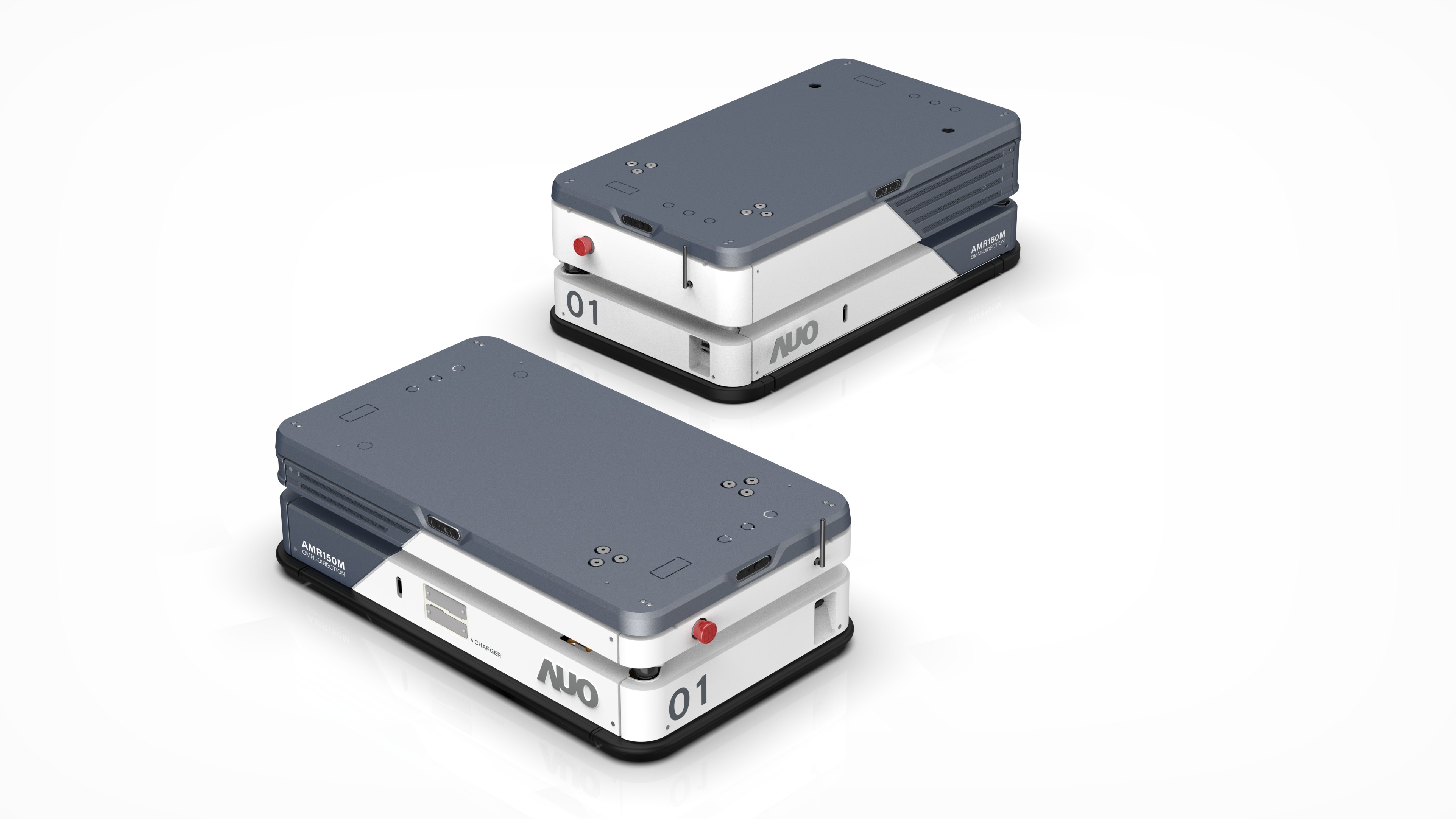

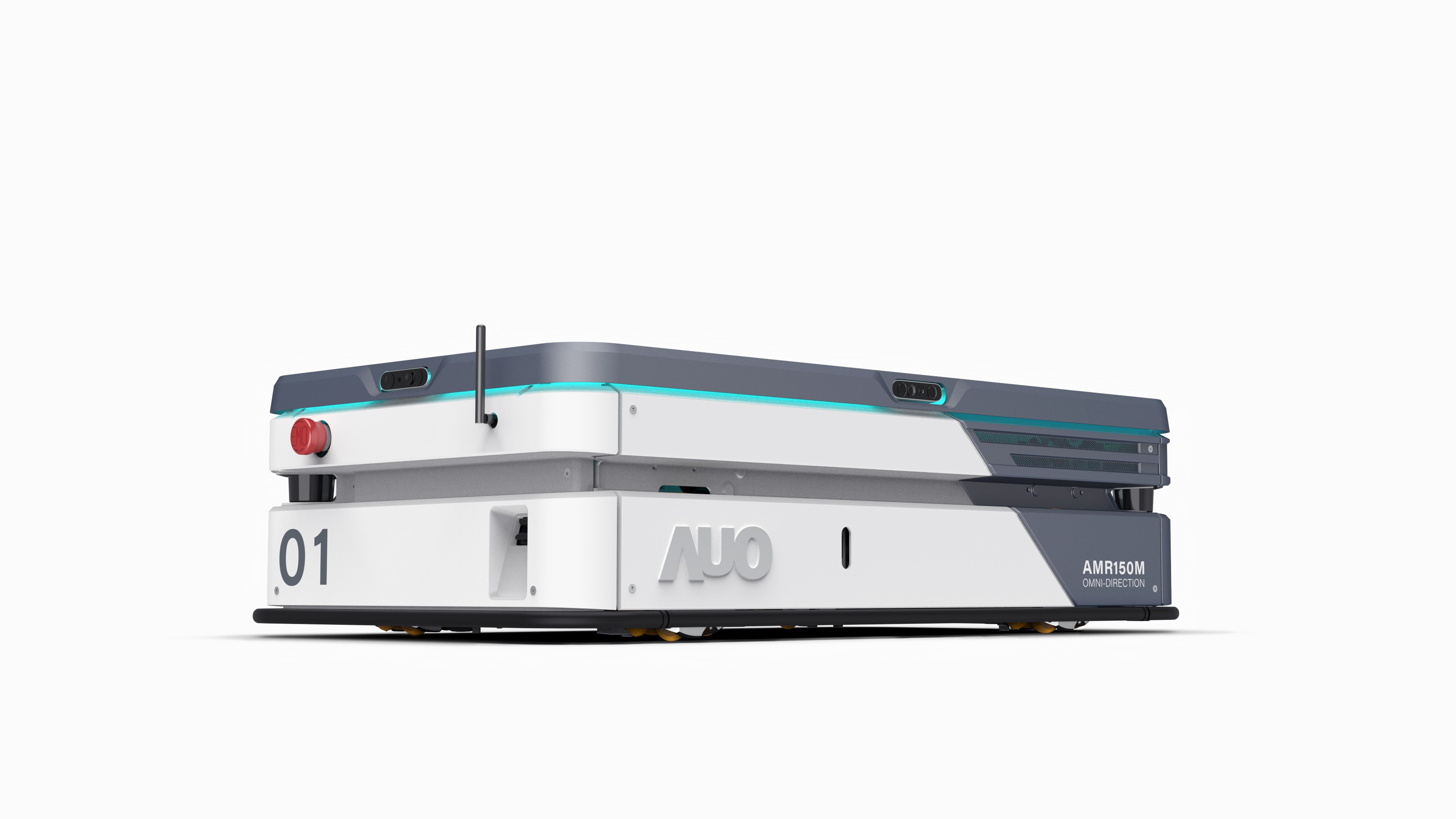

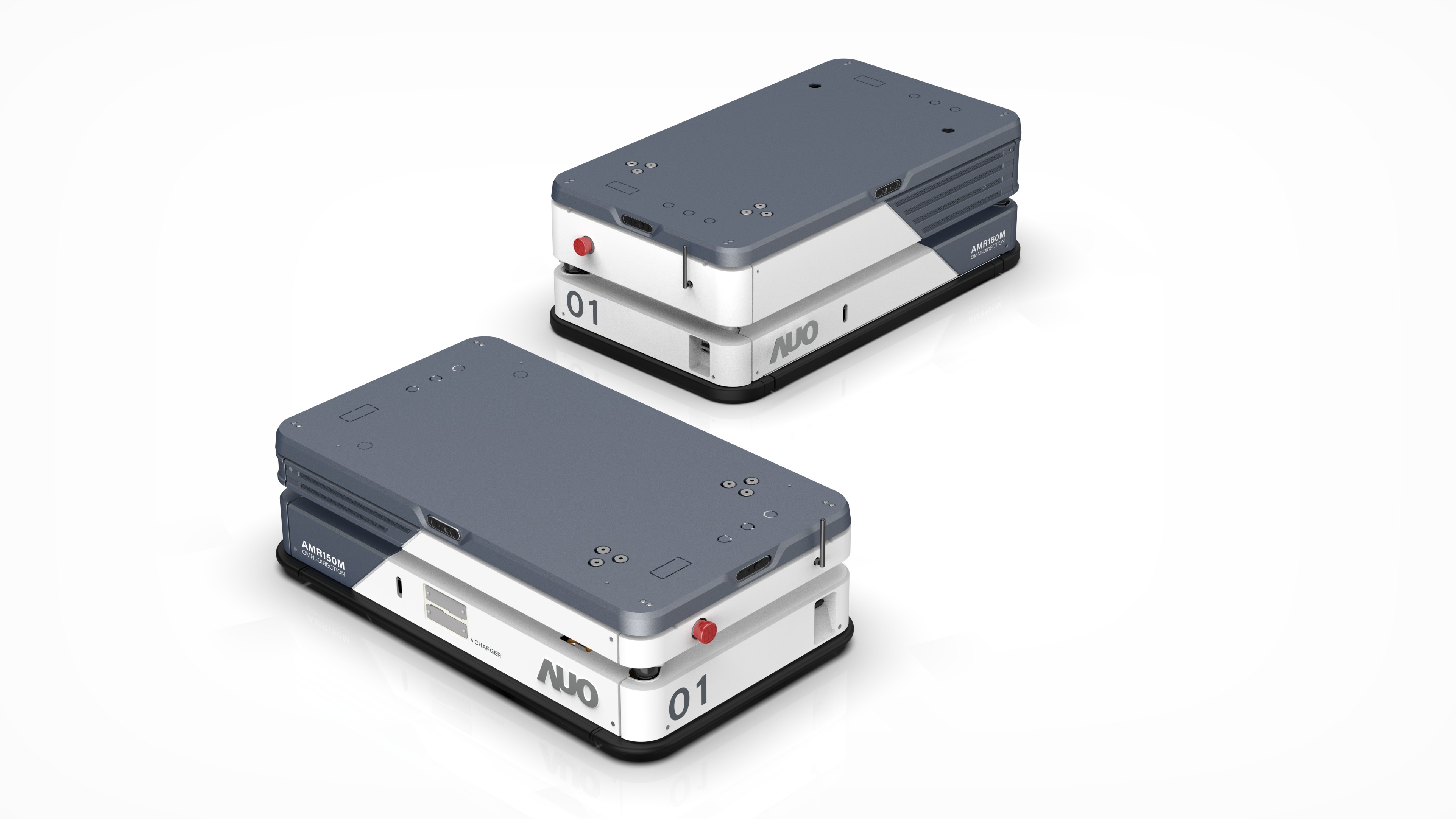

AMR 150M

Background

AMR150M delivers a smarter solution in semiconductor smart factories.

Facing an aging population and rising labor costs, the manufacturing industry is accelerating toward smart automation. Efficient space utilization has become a key factor in advanced production environments.

Product Overview

High Flexibility

High Precision

High Scalability

To address increasing demand for automation in confined spaces, the AMR150M features:

- Designed for narrow (80 cm) spaces

- Modular System for diverse needs

- Perfect for smart manufacturing

Key Feature

01

SLAM Autonomous Navigation

02

Omni- Direction Movement

03

AI Obstacle Detection

04

Safe Human-Robot Collaboration

05

Safe Battery Management

06

Modular System

Made to Move Through 80cm Wide Passages

Modular System for Flexibility and Scalability

Easily configure various functions—robot arms, lifts, conveyors—for flexible use, reducing maintenance and costs.

Robot Module

The AMR integrates a multi-joint robotic arm, offering high flexibility and precision for delicate object handling and manipulation.

- Quality Inspection

- Pick and Place

- ssembly Work

Lifting Module

Equipped with a lifting platform, the AMR enables precise height adjustments for lifting, securing, and transporting materials, optimizing material flow.

- Warehouse Management

- Material Handling

- Assembly Work

Roller Conveyor Module

Designed with a roller conveyor system, the AMR efficiently supports and transports materials, seamlessly integrating with automated conveyor lines.

- Warehouse Automation

- Packaging Handling

- Material Transport

Embrace total 360° mobility

Move diagonally, rotate freely

Certifications

Meeting Rigorous Standards, Designed for the Semiconductor Industry

Designed for semiconductor manufacturing, ensuring high purity and safety, providing reliable automation for advanced chip production.

Certified for International Safety and Quality

01

Compliant with SEMI S8 and S17 standards

02

Passed for Class 1 cleanroom environments tests

03

Earthquake-resistant up to magnitude 7

Sustainability

Strategic Alignment with SDGs

AMR150M boosts factory efficiency and helps address global challenges, promoting sustainable growth.

08 Decent Work and Economic Growth

Building Safe and Dignified Work Environments

- Respecting workers' dignity

- Reducing hazards in industrial settings

- Safeguarding workers’ safety

- Promoting stable employment and economic growth

09 Industry, Innovation, and Infrastructure

Powering Industrial Upgrades Through Smart Technology

- Enhancing industry innovation through intelligent autonomous vehicles

- Strengthening infrastructure

- Building smart factories

12 Responsible Consumption and Production

Promoting Green and Responsible Production

- Reducing energy consumption and waste

- Enabling sustainable and responsible manufacturing

13 Climate Action

Driving Carbon Reduction & Green Transformation

- Utilizing intelligent automation to lower energy use

- Supporting corporate climate action

Specifications

Smart Choices for Your Logistics

Find the perfect autonomous mobile robot to streamline your operations and elevate your efficiency.

Download Brochure

AMR150M

Highlight

Light and agile, perfect for narrow spaces, easily maneuvering through tight environments to maximize space utilization.

Position Accuracy

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Dimension (mm)

L1032 x W 602 x H 372

Payload (kg)

150

Charging Time (h)

1

Driving Mode

Omni-directional Drive

Driving Mode

SLAM

QR code

Sensor

- Safety laser scanners and quad 3D cameras

- Around hardware bumper

Compliance

- SEMI S8

- SEMI S17

Award

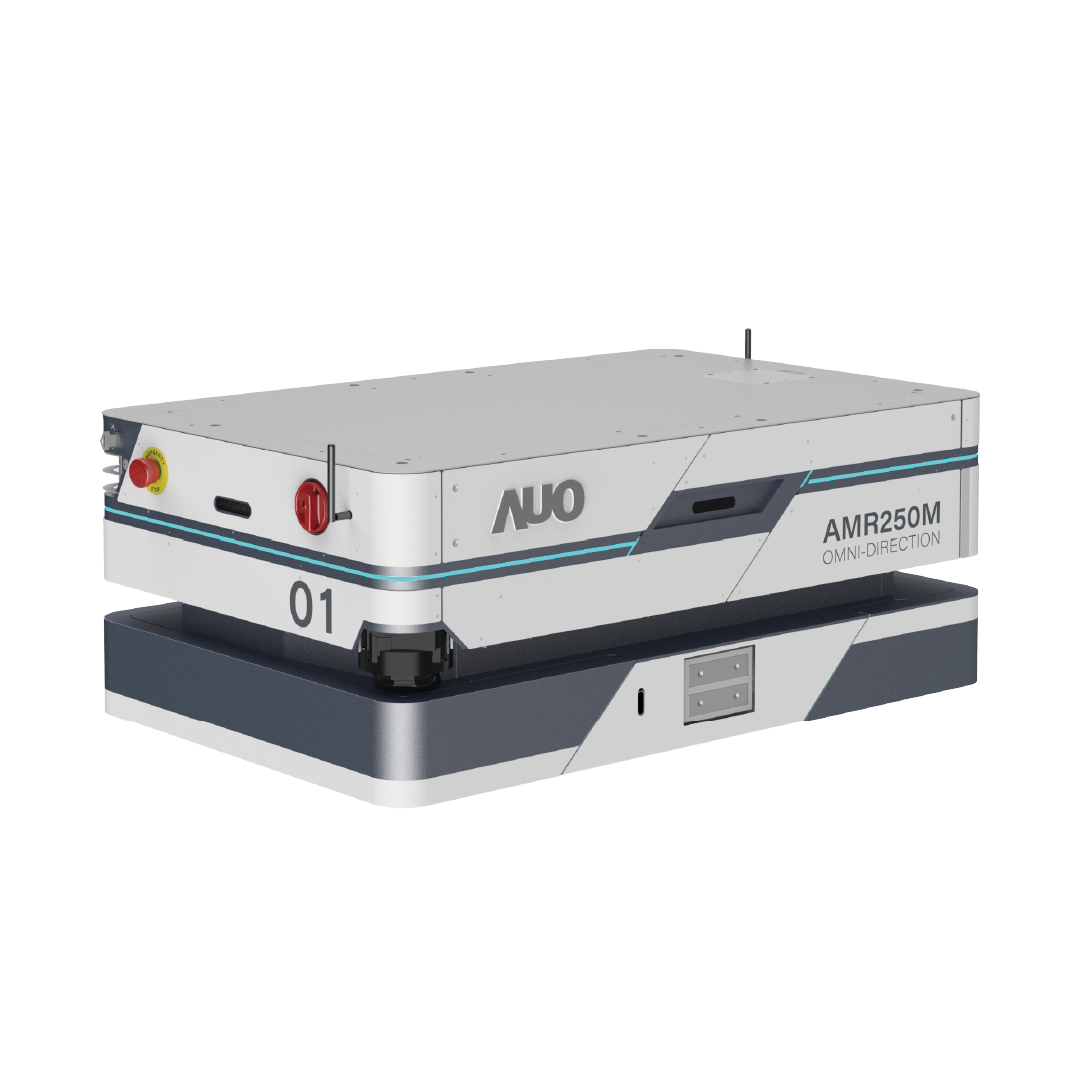

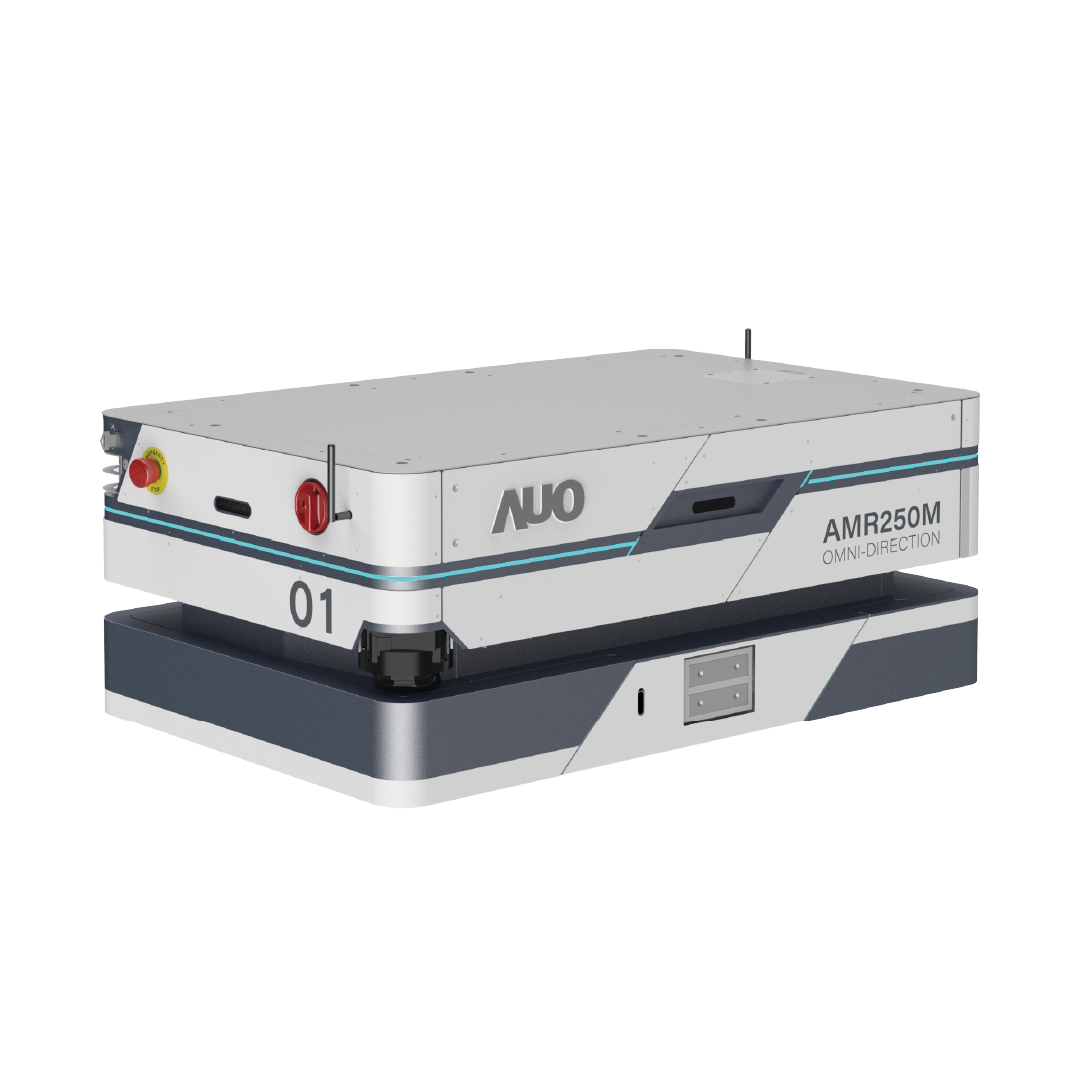

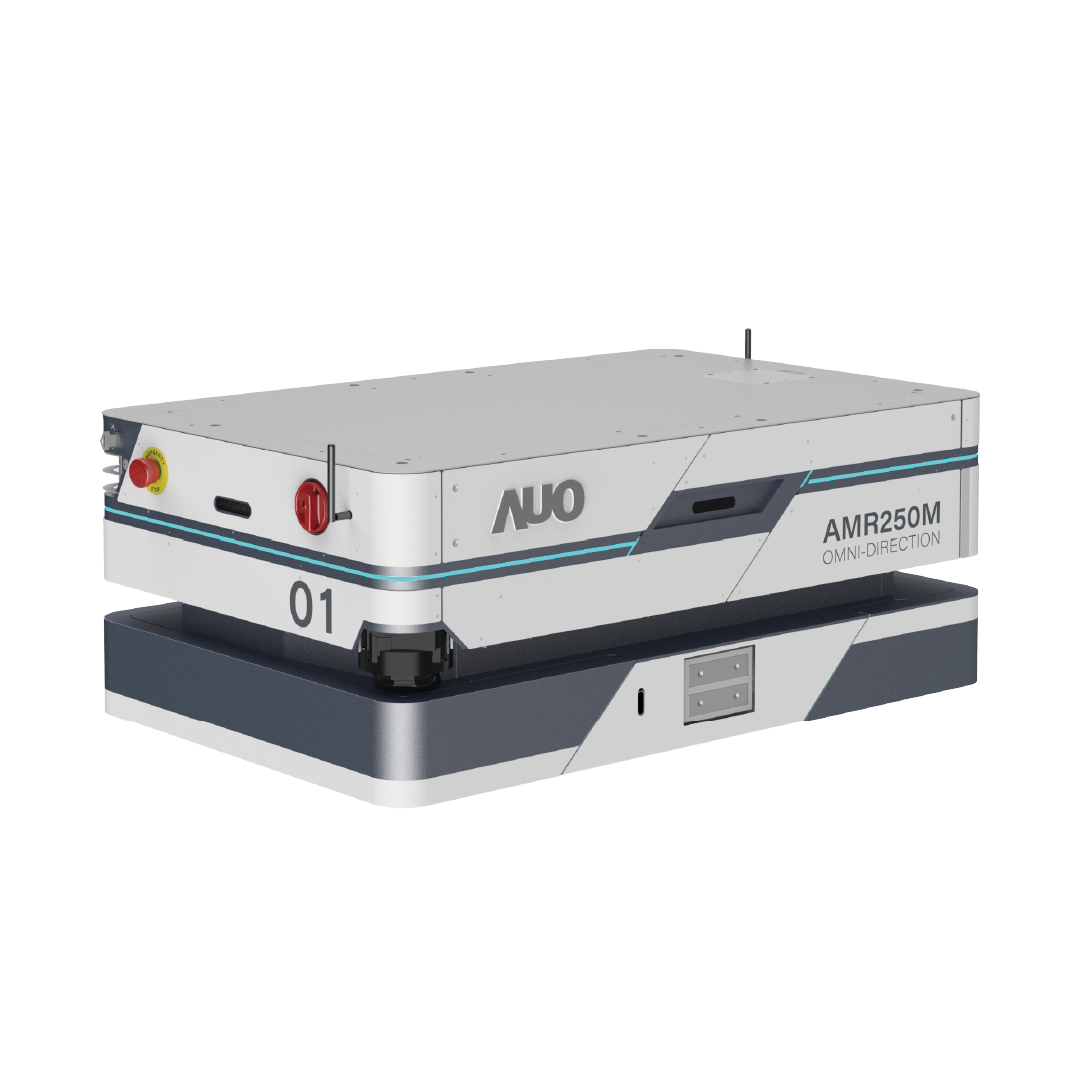

AMR250M

Highlight

Capable of handling heavier loads, ideal for transporting medium-sized goods with enhanced stability and efficiency.

Position Accuracy

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Dimension (mm)

L 1111 x W 714 x H 441

Payload (kg)

250

Charging Time (h)

1

Driving Mode

Omni-directional Drive

Driving Mode

SLAM

Sensor

- Safety laser scanners and quad 3D cameras

- Around hardware bumper

Compliance

- CE: EN ISO 3691-4

- IEC 60204-1

- CE: EN 1175

- CE: EN IEC 61000-6-2:2019

- CE: EN IEC 61000-6-4:2019

- SEMI S2: SEMIS22

- IEC 60204-33

- SEMI S8 / ISO 13849-1

Award

AMR500M

Highlight

Customizable fork modules designed to meet specific operational requirements; fully adaptable with tailored features.

Position Accuracy

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Dimension (mm)

L 1770 x W 800 x H 1805

Payload (kg)

500

Charging Time (h)

1

Driving Mode

Omni-directional Drive

Driving Mode

SLAM

Sensor

- Safety laser scanners and quad 3D cameras

- Around hardware bumper

Compliance

-

Award

-

Software

Fleet Management System

Empowering Your Logistics

AUO Fleet enhances production efficiency and operational safety by optimizing the dispatch of autonomous mobile robots (AMRs) and providing critical data insights. Its user-centric UI offers valuable support across all organizational levels.

Interested in AMR150M ?

Watch our introduction video or refer to our brochure for detailed product information. If you have any questions, feel free to contact us — we're happy to assist!

AMR Series Video

Brochure

Intelligent Logistics, Revolutionizing Efficiency

Precise Navigation, Agile Operation, Building the Next Generation Smart Factory

AMR 150M

Background

AMR150M delivers a smarter solution in semiconductor smart factories.

Facing an aging population and rising labor costs, the manufacturing industry is accelerating toward smart automation. Efficient space utilization has become a key factor in advanced production environments.

Product Overview

High Flexibility

High Precision

High Scalability

To address increasing demand for automation in confined spaces, the AMR150M features:

- Designed for narrow (80 cm) spaces

- Modular System for diverse needs

- Perfect for smart manufacturing

Key Feature

01

SLAM Autonomous Navigation

02

Omni- Direction Movement

03

AI Obstacle Detection

04

Safe Human-Robot Collaboration

05

Safe Battery Management

06

Modular System

Made to Move Through 80cm Wide Passages

Modular System for Flexibility and Scalability

Easily configure various functions—robot arms, lifts, conveyors—for flexible use, reducing maintenance and costs.

Robot Module

The AMR integrates a multi-joint robotic arm, offering high flexibility and precision for delicate object handling and manipulation.

- Quality Inspection

- Pick and Place

- ssembly Work

Lifting Module

Equipped with a lifting platform, the AMR enables precise height adjustments for lifting, securing, and transporting materials, optimizing material flow.

- Warehouse Management

- Material Handling

- Assembly Work

Roller Conveyor Module

Designed with a roller conveyor system, the AMR efficiently supports and transports materials, seamlessly integrating with automated conveyor lines.

- Warehouse Automation

- Packaging Handling

- Material Transport

Embrace total 360° mobility

Move diagonally, rotate freely

Certifications

Meeting Rigorous Standards, Designed for the Semiconductor Industry

Designed for semiconductor manufacturing, ensuring high purity and safety, providing reliable automation for advanced chip production.

Certified for International Safety and Quality

01

Compliant with SEMI S8 and S17 standards

02

Passed for Class 1 cleanroom environments tests

03

Earthquake-resistant up to magnitude 7

Sustainability

Strategic Alignment with SDGs

AMR150M boosts factory efficiency and helps address global challenges, promoting sustainable growth.

08 Decent Work and Economic Growth

Building Safe and Dignified Work Environments

- Respecting workers' dignity

- Reducing hazards in industrial settings

- Safeguarding workers’ safety

- Promoting stable employment and economic growth

09 Industry, Innovation, and Infrastructure

Powering Industrial Upgrades Through Smart Technology

- Enhancing industry innovation through intelligent autonomous vehicles

- Strengthening infrastructure

- Building smart factories

12 Responsible Consumption and Production

Promoting Green and Responsible Production

- Reducing energy consumption and waste

- Enabling sustainable and responsible manufacturing

13 Climate Action

Driving Carbon Reduction & Green Transformation

- Utilizing intelligent automation to lower energy use

- Supporting corporate climate action

Specifications

Smart Choices for Your Logistics

Find the perfect autonomous mobile robot to streamline your operations and elevate your efficiency.

Download Brochure

AMR150M

Highlight

Light and agile, perfect for narrow spaces, easily maneuvering through tight environments to maximize space utilization.

Position Accuracy

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Dimension (mm)

L1032 x W 602 x H 372

Payload (kg)

150

Charging Time (h)

1

Driving Mode

Omni-directional Drive

Driving Mode

SLAM

QR code

Sensor

- Safety laser scanners and quad 3D cameras

- Around hardware bumper

Compliance

- SEMI S8

- SEMI S17

Award

AMR250M

Highlight

Capable of handling heavier loads, ideal for transporting medium-sized goods with enhanced stability and efficiency.

Position Accuracy

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Dimension (mm)

L 1111 x W 714 x H 441

Payload (kg)

250

Charging Time (h)

1

Driving Mode

Omni-directional Drive

Driving Mode

SLAM

Sensor

- Safety laser scanners and quad 3D cameras

- Around hardware bumper

Compliance

- CE: EN ISO 3691-4

- IEC 60204-1

- CE: EN 1175

- CE: EN IEC 61000-6-2:2019

- CE: EN IEC 61000-6-4:2019

- SEMI S2: SEMIS22

- IEC 60204-33

- SEMI S8 / ISO 13849-1

Award

AMR500M

Highlight

Customizable fork modules designed to meet specific operational requirements; fully adaptable with tailored features.

Position Accuracy

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Dimension (mm)

L 1770 x W 800 x H 1805

Payload (kg)

500

Charging Time (h)

1

Driving Mode

Omni-directional Drive

Driving Mode

SLAM

Sensor

- Safety laser scanners and quad 3D cameras

- Around hardware bumper

Compliance

-

Award

-

Software

Fleet Management System

Empowering Your Logistics

AUO Fleet enhances production efficiency and operational safety by optimizing the dispatch of autonomous mobile robots (AMRs) and providing critical data insights. Its user-centric UI offers valuable support across all organizational levels.

Interested in AMR150M ?

Watch our introduction video or refer to our brochure for detailed product information. If you have any questions, feel free to contact us — we're happy to assist!

AMR Series Video

Brochure

Intelligent Logistics,

Revolutionizing Efficiency

Precise Navigation,

Agile Operation,

Building the Next Generation Smart Factory

AMR 150M

Background

AMR150M delivers a smarter solution in semiconductor smart factories.

Facing an aging population and rising labor costs, the manufacturing industry is accelerating toward smart automation. Efficient space utilization has become a key factor in advanced production environments.

Product Overview

High Flexibility

High Precision

High Scalability

To address increasing demand for automation in confined spaces, the AMR150M features:

- Designed for narrow passages (as narrow as 80 centimeters)

- Modular multi-function design to enhance flexibility and efficiency

- Supports various upper-layer modules for diverse manufacturing needs

- Ideal choice for smart manufacturing

Key Feature

01

SLAM Autonomous Navigation

02

Omni- Direction Movement

03

AI Obstacle Detection

04

Safe Human-Robot Collaboration

05

Safe Battery Management

06

Modular System

Made to Move Through 80cm Wide Passages

Modular System for Flexibility and Scalability

Quickly configure diverse functions according to different needs. Whether it’s robotic arms, lifting modules, or conveyor belts, all can be flexibly combined, helping to reduce maintenance and equipment costs.

Robot Module

- Quality Inspection

- Pick and Place

- ssembly Work

Lifting Module

- Warehouse Management

- Material Handling

- Assembly Work

Roller Conveyor Module

- Warehouse Automation

- Packaging Handling

- Material Transport

Embrace total 360° mobility

Move diagonally, rotate freely

Certifications

Meeting Rigorous Standards, Designed for the Semiconductor Industry

Developed specifically for semiconductor manufacturing environments, ensuring high purity and strict safety standards, providing reliable automation solutions for the advanced chip industry.

Certified for International Safety and Quality

01

Compliant with SEMI S8 and S17 standards

02

Passed for Class 1 cleanroom environments tests

03

Earthquake-resistant up to magnitude 7

Sustainability

Strategic Alignment with SDGs

AMR150M boosts factory efficiency and helps address global challenges, promoting sustainable growth.

08 Decent Work and Economic Growth

Building Safe and Dignified Work Environments

Creating safe working environments that respect dignity, reducing hazards in industrial settings, safeguarding workers’ safety, and promoting stable employment and economic growth.

09 Industry, Innovation, and Infrastructure

Powering Industrial Upgrades Through Smart Technology

Driving industrial upgrading and digital transformation, enhancing industry innovation through intelligent autonomous vehicles, strengthening infrastructure, and building smart factories.

12 Responsible Consumption and Production

Promoting Green and Responsible Production

Promoting resource efficiency and green production, reducing energy use and waste, and enabling more sustainable and responsible manufacturing.

13 Climate Action

Driving Carbon Reduction & Green Transformation

Reducing carbon footprints and promoting green transformation, utilizing intelligent automation to lower energy consumption, supporting corporate climate action.

Specifications

Smart Choices for Your Logistics

Find the perfect autonomous mobile robot to streamline your operations and elevate your efficiency.

Download Brochure

Technical Specification

AMR150M

AMR250M

AMR500M

Highlight

Light and agile, perfect for narrow spaces, easily maneuvering through tight environments to maximize space utilization.

Capable of handling heavier loads, ideal for transporting medium-sized goods.

Customizable fork modules designed to meet specific operational requirements; fully adaptable with tailored features.

Position Accuracy

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Dimension (mm)

L1032 x W 602 x H 372

L 1111 x W 714 x H 441

L 1770 x W 800 x H 1805

Payload (kg)

150

250

500

Charging Time (h)

1

1

1

Driving Mode

Omni-directional Drive (360° Movement )

Omni-directional Drive (360° Movement )

Omni-directional Drive (360° Movement )

Navigation

SLAM

QR code

SLAM

SLAM

Sensor

Safety laser scanners and quad 3D cameras

Safety laser scanners and quad 3D cameras

Safety laser scanners and quad 3D cameras

Around hardware bumper

Around hardware bumper

Around hardware bumper

Compliance

• SEMI S8

• SEMI S17

• CE: EN ISO 3691-4

• IEC 60204-1

• CE: EN 1175

• CE: EN IEC 61000-6-2:2019

• CE: EN IEC 61000-6-4:2019

• SEMI S2: SEMIS22

• IEC 60204-33

• SEMI S8 / ISO 13849-1

-

Award

-

Software

Fleet Management System

AUO Fleet enhances production efficiency and operational safety by optimizing the dispatch of autonomous mobile robots (AMRs) and providing critical data insights. Its user-centric UI offers valuable support across all organizational levels.

Interested in AMR150M ?

Watch our introduction video or refer to our brochure for detailed product information.

If you have any questions, feel free to contact us — we're happy to assist!

AMR Series Video

Brochure

Intelligent Logistics,

Revolutionizing Efficiency

Precise Navigation,

Agile Operation,

Building the Next Generation Smart Factory

AMR 150M

Background

AMR150M delivers a smarter solution in semiconductor smart factories.

Facing an aging population and rising labor costs, the manufacturing industry is accelerating toward smart automation. Efficient space utilization has become a key factor in advanced production environments.

Product Overview

High Flexibility

High Precision

High Scalability

To address the increasing demand for automation in confined spaces, the AMR150M is specifically designed for narrow passages (as narrow as 80 centimeters). It features a modular multi-function design to enhance production flexibility and efficiency. Its modular architecture supports various upper-layer modules to meet diverse manufacturing needs, making it the ideal choice for smart manufacturing.

Key Feature

01

SLAM Autonomous Navigation

02

Omni- Direction Movement

03

AI Obstacle Detection

04

Safe Human-Robot Collaboration

05

Safe Battery Management

06

Modular System

Made to Move Through 80cm Wide Passages

Modular System for Flexibility and Scalability

Quickly configure diverse functions according to different needs. Whether it’s robotic arms, lifting modules, or conveyor belts, all can be flexibly combined, helping to reduce maintenance and equipment costs.

Robot Module

# Quality Inspection

# Assembly Work

# Pick and Place

The AMR integrates a multi-joint robotic arm, offering high flexibility and precision for delicate object handling and manipulation.

Lifting Module

# Material Handling

# Assembly Work

# Warehouse Management

Equipped with a lifting platform, the AMR enables precise height adjustments for lifting, securing, and transporting materials, optimizing material flow.

Roller Conveyor Module

# Material Transport

# Packaging Handling

# Warehouse Automation

Designed with a roller conveyor system, the AMR efficiently supports and transports materials, seamlessly integrating with automated conveyor lines.

Embrace total 360° mobility

Move diagonally, rotate freely

Certifications

Meeting Rigorous Standards, Designed for the Semiconductor Industry

Developed specifically for semiconductor manufacturing environments, ensuring high purity and strict safety standards, providing reliable automation solutions for the advanced chip industry.

Certified for International Safety and Quality

01

Compliant with SEMI S8 and S17 standards

02

Passed for Class 1 cleanroom environments tests

03

Earthquake-resistant up to magnitude 7

Sustainability

Strategic Alignment with SDGs

Our AMR150M automation solution closely aligns with various critical themes of the United Nations Sustainable Development Goals (SDGs), focusing on the following key areas:

AMR150M not only enhances factory efficiency but also actively responds to global challenges, working together to create a future that harmonizes economic development with environmental sustainability.

08 Decent Work and Economic Growth

Building Safe and Dignified Work Environments

Creating safe working environments that respect dignity, reducing hazards in industrial settings, safeguarding workers’ safety, and promoting stable employment and economic growth.

09 Industry, Innovation, and Infrastructure

Powering Industrial Upgrades Through Smart Technology

Driving industrial upgrading and digital transformation, enhancing industry innovation through intelligent autonomous vehicles, strengthening infrastructure, and building smart factories.

12 Responsible Consumption and Production

Promoting Green and Responsible Production

Promoting resource efficiency and green production, reducing energy use and waste, and enabling more sustainable and responsible manufacturing.

13 Climate Action

Driving Carbon Reduction & Green Transformation

Reducing carbon footprints and promoting green transformation, utilizing intelligent automation to lower energy consumption, supporting corporate climate action.

Specifications

Smart Choices for Your Logistics

Find the perfect autonomous mobile robot to streamline your operations and elevate your efficiency.

Download Brochure

Technical Specification

AMR150M

AMR250M

AMR500M

Highlight

Light and agile, perfect for narrow spaces, easily maneuvering through tight environments to maximize space utilization.

Capable of handling heavier loads, ideal for transporting medium-sized goods.

Customizable fork modules designed to meet specific operational requirements; fully adaptable with tailored features.

Position Accuracy

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Dimension (mm)

L1032 x W 602 x H 372

L 1111 x W 714 x H 441

L 1770 x W 800 x H 1805

Payload (kg)

150

250

500

Charging Time (h)

1

1

1

Driving Mode

Omni-directional Drive (360° Movement )

Omni-directional Drive (360° Movement )

Omni-directional Drive (360° Movement )

Navigation

SLAM

QR code

SLAM

SLAM

Sensor

Safety laser scanners and quad 3D cameras

Safety laser scanners and quad 3D cameras

Safety laser scanners and quad 3D cameras

Around hardware bumper

Around hardware bumper

Around hardware bumper

Compliance

• SEMI S8

• SEMI S17

• CE: EN ISO 3691-4

• IEC 60204-1

• CE: EN 1175

• CE: EN IEC 61000-6-2:2019

• CE: EN IEC 61000-6-4:2019

• SEMI S2: SEMIS22

• IEC 60204-33

• SEMI S8 / ISO 13849-1

-

Award

-

Software

Fleet Management System

Empowering Your Logistics

AUO Fleet enhances production efficiency and operational safety by optimizing the dispatch of autonomous mobile robots (AMRs) and providing critical data insights. Its user-centric UI offers valuable support across all organizational levels.

Interested in AMR150M ?

Watch our introduction video or refer to our brochure for detailed product information. If you have any questions, feel free to contact us — we're happy to assist!

AMR Series Video

Brochure

Intelligent Logistics,

Revolutionizing Efficiency

Precise Navigation,

Agile Operation,

Building the Next Generation Smart Factory

AMR 150M

Background

AMR150M delivers a smarter solution in semiconductor smart factories.

Facing an aging population and rising labor costs, the manufacturing industry is accelerating toward smart automation. Efficient space utilization has become a key factor in advanced production environments.

Product Overview

High Flexibility

High Precision

High Scalability

To address the increasing demand for automation in confined spaces, the AMR150M is specifically designed for narrow passages (as narrow as 80 centimeters). It features a modular multi-function design to enhance production flexibility and efficiency. Its modular architecture supports various upper-layer modules to meet diverse manufacturing needs, making it the ideal choice for smart manufacturing.

Key Feature

01

SLAM Autonomous Navigation

02

Omni- Direction Movement

03

AI Obstacle Detection

04

Safe Human-Robot Collaboration

05

Safe Battery Management

06

Modular System

Made to Move Through 80cm Wide Passages

Modular System for Flexibility and Scalability

Quickly configure diverse functions according to different needs. Whether it’s robotic arms, lifting modules, or conveyor belts, all can be flexibly combined, helping to reduce maintenance and equipment costs.

Robot Module

# Quality Inspection

# Assembly Work

# Pick and Place

The AMR integrates a multi-joint robotic arm, offering high flexibility and precision for delicate object handling and manipulation.

Lifting Module

# Material Handling

# Assembly Work

# Warehouse Management

Equipped with a lifting platform, the AMR enables precise height adjustments for lifting, securing, and transporting materials, optimizing material flow.

Roller Conveyor Module

# Material Transport

# Packaging Handling

# Warehouse Automation

Designed with a roller conveyor system, the AMR efficiently supports and transports materials, seamlessly integrating with automated conveyor lines.

Move diagonally, rotate freely

Embrace total 360° mobility

Certifications

Meeting Rigorous Standards, Designed for the Semiconductor Industry

Developed specifically for semiconductor manufacturing environments, ensuring high purity and strict safety standards, providing reliable automation solutions for the advanced chip industry.

Certified for International Safety and Quality

01

Compliant with SEMI S8 and S17 standards

02

Passed for Class 1 cleanroom environments tests

03

Earthquake-resistant up to magnitude 7

Sustainability

Strategic Alignment with SDGs

Our AMR150M automation solution closely aligns with various critical themes of the United Nations Sustainable Development Goals (SDGs), focusing on the following key areas:

AMR150M not only enhances factory efficiency but also actively responds to global challenges, working together to create a future that harmonizes economic development with environmental sustainability.

08 Decent Work and Economic Growth

Building Safe and Dignified Work Environments

Creating safe working environments that respect dignity, reducing hazards in industrial settings, safeguarding workers’ safety, and promoting stable employment and economic growth.

09 Industry, Innovation, and Infrastructure

Powering Industrial Upgrades Through Smart Technology

Driving industrial upgrading and digital transformation, enhancing industry innovation through intelligent autonomous vehicles, strengthening infrastructure, and building smart factories.

12 Responsible Consumption and Production

Promoting Green and Responsible Production

Promoting resource efficiency and green production, reducing energy use and waste, and enabling more sustainable and responsible manufacturing.

13 Climate Action

Driving Carbon Reduction & Green Transformation

Reducing carbon footprints and promoting green transformation, utilizing intelligent automation to lower energy consumption, supporting corporate climate action.

Specifications

Smart Choices for Your Logistics

Find the perfect autonomous mobile robot to streamline your operations and elevate your efficiency.

Download Brochure

Technical Specification

AMR150M

AMR250M

AMR500M

Highlight

Light and agile, perfect for narrow spaces, easily maneuvering through tight environments to maximize space utilization.

Capable of handling heavier loads, ideal for transporting medium-sized goods.

Customizable fork modules designed to meet specific operational requirements; fully adaptable with tailored features.

Position Accuracy

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Accuracy +/- 10mm, +/- 1˚ (with landmark)

Dimension (mm)

L1032 x W 602 x H 372

L 1111 x W 714 x H 441

L 1770 x W 800 x H 1805

Payload (kg)

150

250

500

Charging Time (h)

1

1

1

Driving Mode

Omni-directional Drive (360° Movement )

Omni-directional Drive (360° Movement )

Omni-directional Drive (360° Movement )

Navigation

SLAM

QR code

SLAM

SLAM

Sensor

Safety laser scanners and quad 3D cameras

Safety laser scanners and quad 3D cameras

Safety laser scanners and quad 3D cameras

Around hardware bumper

Around hardware bumper

Around hardware bumper

Compliance

• SEMI S8

• SEMI S17

• CE: EN ISO 3691-4 / IEC 60204-1

• CE: EN 1175

• CE: EN IEC 61000-6-2:2019

• CE: EN IEC 61000-6-4:2019

• SEMI S2: SEMIS22 / IEC 60204-33

• SEMI S8 / ISO 13849-1

-

Award

-

Software

Fleet Management System

Empowering Your Logistics

AUO Fleet enhances production efficiency and operational safety by optimizing the dispatch of autonomous mobile robots (AMRs) and providing critical data insights. Its user-centric UI offers valuable support across all organizational levels.

Interested in AMR150M ?

Watch our introduction video or refer to our brochure for detailed product information.

If you have any questions, feel free to contact us — we're happy to assist!

AMR Series Video

Brochure